Contract manufacturing

Compound Die Stamping

Rapid Prototype Turnaround

Committed to exceeding expectations for quality and rapid turnaround, and meeting high-quality sheet metal parts.

On-Demand Sheet Metal

Whether it is rapid prototyping & large-volume manufacturing, we will implement it according to customer needs and standards.

Real Fabricators Price

Integrate product design, bending, stamping, cutting, surface treatment, etc. to provide a series of manufacturing solutions.

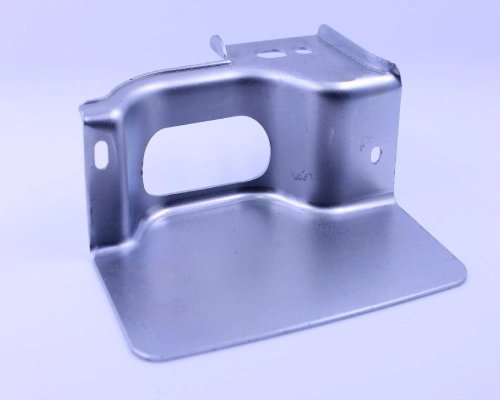

Compound Die Stamping Services

Compound die stamping is a high-efficiency and low-cost precision metal stamping manufacturing process. It is suitable for small and medium-sized metal stamping projects. It can not only ensure the precision tolerances required for part design, but also has a lower manufacturing cost than progressive die molds.

At Supro MFG, we have a professional compound die stamping production line, with 12 high-speed presses ranging from 10 tons to 340 tons. All equipment is dedicated to running compound die stamping dies. With a professional stamping technology team, it can meet the needs of metal stamping parts in all industries and provide competitive cost quotations from Chinese compound die stamping manufacturers.

We provide a series of precision stamping solutions, including: mold design and manufacturing, product design optimization, DFM manufacturability report, product mass production, welding, surface treatment, heat treatment, packaging, and transportation to the world.

Talk to our mold experts now, to help you create unexpected metal stamping projects faster.

What is Compound Die Stamping

Compound die stamping is a stamping process similar to progressive die stamping, but the difference is that the progressive die has a lot of cavities arranged in an orderly manner on the die, and the material will be shaped by different cavities after being formed by the die. Finally we can get a complete product.

However, Compound dies combines two or more feature forming modules with multiple sliders and mechanical settings. In a stamping cycle, different details of the part are created, such as: cutting blanks, punching, Stretching concave-convex type and deep-drawing molding, etc.

Although it seems that the mold has performed a movement, the ingenious mechanical transmission principle allows all the features to be completed at one time and maintains extremely strong quality stability.

Compound die stamping is very suitable for production orders with limited budgets and small and medium-sized quantities, and can demonstrate very high efficiency and low labor costs, with market-competitive manufacturing technology.

sheet metal stamping services

compound die stamping

material solutions

Supro MFG offers a robust stockpile of materials to help your products can get up and running with a quick turnaround.

Within an hour, the metal material is ready for the sheet metal bending process.

Aluminum Alloy

stainless steel

Copper

steel

Other

1060

6061-T6 / T5

6063

5052-O

5083

5754

7075

2A12

201

303

304

316

316L

420

430

440

H62

H65

H68

H90

C10100

C11000

C12000

C51100

Q235 - F

Q255

16Mn

12CrMo

# 45

20 G

Corrugated Steel Sheets

Fluorocarbon color steel

Embossed panels

Galvanized sheet

0.6mm - 200mm

1220mm * 2440mm

Custom roll & Strips

0.05mm - 300mm

1220mm * 2440mm

Custom roll & Strips

0.5mm - 6mm

1200mm * 4000mm

Custom roll & Strips

0.5mm - 500mm

1500mm * 6000mm

Custom roll & Strips

WHY CHOOSE

Advantages of compound die stamping

Compound die stamping is widely cited because it has a very high cost performance. More and more small and medium enterprises and project purchasers choose to use compound dies to complete their projects.

Different from the traditional single-die stamping, which requires constant replacement of molds for different manufacturing processes, compound dies tooling can perform multiple different processes in one stamping cycle to maintain stable quality, reduce errors caused by continuous operation of parts, and reduce the cost of molds. The upper part is much less than the similar progressive die.

Fast production speed: compound die stamping can produce 1500 products per hour.

High-efficiency operation: multiple forming and cutting actions can be performed in one stamping cycle, reducing the need for multiple mold combinations.

Economic benefits: high-efficiency production and low-cost molds help to save more production costs and time costs.

Consistency of parts: Due to automatic operation, there are no too many errors in the mold, reducing human quality risks and maintaining consistent quality.

Are you looking for a reliable composite die stamping manufacturer?

Supro MFG can be solved smoothly, you do not need to bear any risk, protect your investment security.